Measured with an accuracy of 1 micron and guaranteed for 10 years! Reducing the defect rate and costs of machining!

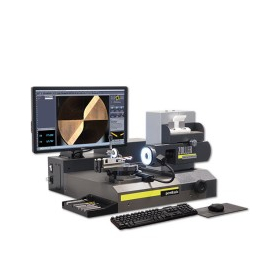

ZOLLER's new generation tool measuring device offers a significant advantage with its measurement precision of 1 micron, and this accuracy is guaranteed for 5 years and even 10 years. High-precision measurements enable cost reduction, efficiency improvement, and lower defect rates! For example, in a case where one-shot machining was made possible through boring processing, a cost reduction of 1.2 million yen per year has been achieved.

*As it is a precision measuring instrument, annual inspections (calibrations) are necessary, and if you are receiving this paid service, the guarantee extends to 10 years.

*We are currently offering a point document explaining the benefits of introducing high-precision tool measuring devices! For more details, please download from the form below.

【Features】

◆ One-shot machining is possible with boring processing!

◆ Height adjustment of milling cutters is highly precise!

◆ Rapid measurement of multiple locations, such as stepped tools!

◆ Measurement accuracy and repeatability are in the micron range!

*Thanks to fully automated measurements, anyone can obtain the same measurement results. For more details, please contact us or download the catalog to view.